Missiles Military

The Titan II ICBM was the successor to the Titan I, with double the payload. Unlike the Titan I, it used hydrazine-based hypergolic propellant which was storable and reliably ignited. This reduced time to launch and permitted it to be launched from its silo. Titan II carried the largest single warhead of any American ICBM.

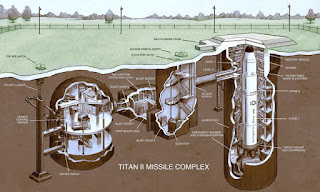

The missile consists of a two-stage, rocket engine powered vehicle and a re-entry vehicle (RV). Provisions are included for in-flight separation of Stage II from Stage I, and separation of the RV from Stage II. Stage I and Stage II vehicles each contain propellant and pressurization, rocket engine, hydraulic and electrical systems, and explosive components. In addition, Stage II contains the flight control system and missile guidance system. Stage I contained three gyros and the Autopilot. The Autopilot attempted to keep the missile straight during first stage flight and sent commands to the Inertial Measurement Unit (IMU) on the 2nd stage. The IMU would compensate and send steering commands to the engine actuators.

The Titan II was an intercontinental ballistic missile (ICBM) and space launcher developed by the Glenn L. Martin Company from the earlier Titan I missile. Titan II was originally designed and used as an ICBM, but was later used as a medium-lift space launch vehicle to carry payloads for the United States Air Force (USAF), National Aeronautics and Space Administration (NASA) and National Oceanic and Atmospheric Administration (NOAA). Those payloads included the USAF Defense Meteorological Satellite Program (DMSP), the NOAA weather satellites, and NASA's Gemini manned space capsules. The modified Titan II SLVs (Space Launch Vehicles) were launched from Vandenberg Air Force Base, California up until 2003.

The Titan II ICBM was the successor to the Titan I, with double the payload. Unlike the Titan I, it used hydrazine-based hypergolic propellant which was storable and reliably ignited. This reduced time to launch and permitted it to be launched from its silo. Titan II carried the largest single warhead of any American ICBM.

The missile consists of a two-stage, rocket engine powered vehicle and a re-entry vehicle (RV). Provisions are included for in-flight separation of Stage II from Stage I, and separation of the RV from Stage II. Stage I and Stage II vehicles each contain propellant and pressurization, rocket engine, hydraulic and electrical systems, and explosive components. In addition, Stage II contains the flight control system and missile guidance system. Stage I contained three gyros and the Autopilot. The Autopilot attempted to keep the missile straight during first stage flight and sent commands to the Inertial Measurement Unit (IMU) on the 2nd stage. The IMU would compensate and send steering commands to the engine actuators.

The airframe is a two-stage, aerodynamically stable structure that houses and protects the airborne missile equipment during powered flight. The missile guidance system enables the shutdown and staging enable relay to initiate Stage I separation. Each stage is 10 feet (3.0 m) in diameter and has fuel and oxidizer tanks in tandem, with the walls of the tanks forming the skin of the missile in those areas. External conduits are attached to the outside surface of the tanks to provide passage for the wire bundles and tubing. Access doors are provided on the missile forward, aft and between-tanks structure for inspection and maintenance. A removable cover for tank entry is located on the forward dome of each tank. More details